Fill Valves are the heart of a tank-level control system (making the control panel the brain). There are two common types of fill valves, Float, and Electronic, used in commercial building tank fill applications. While both can be effective, the electronic float valves (and paired controls) provide extended life through even wear, improved communication with the BAS, and ease of service.

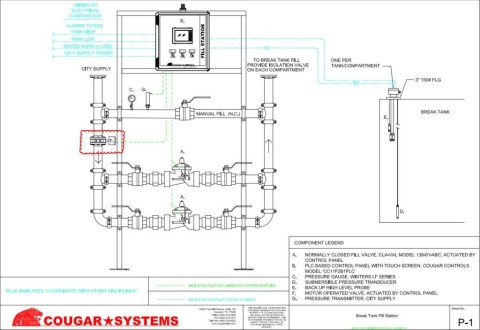

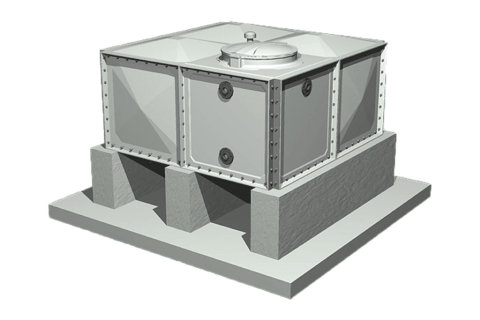

On this Tech Talk, we are going to cover the difference between the float style and electronic style fill valves for storage tanks. So in the city of Houston we have this code requirement where you have to go through an atmospheric storage tank before you add on a pressure boosting system.

To pressurize your building, you got two options on which type of fill valves, you would use for that tank. The style that’s been around for a long time, is going to be this one 2401 float valve from Cla Val using the 100-01 Hytrol valve, base valve configuration and we’ve got this CF1C1 Pilot assembly here that is controlling the water on, and off the valve to open and close it.Now, this is a mechanical assembly you got the float hanging down in the tank and literally just like the back of a toilet, you know, the float goes up the valve is going to turn off the flow goes down the valve is going to open up and refill the tank. Problem with these style valves is it’s mounted up on top of the tank it can be difficult and even dangerous to get in and service it and it’s all mechanical in terms of how you make any adjustments, how it turns on and off and when you have two of them, there’s no way to alternate which valve is the lead valve.